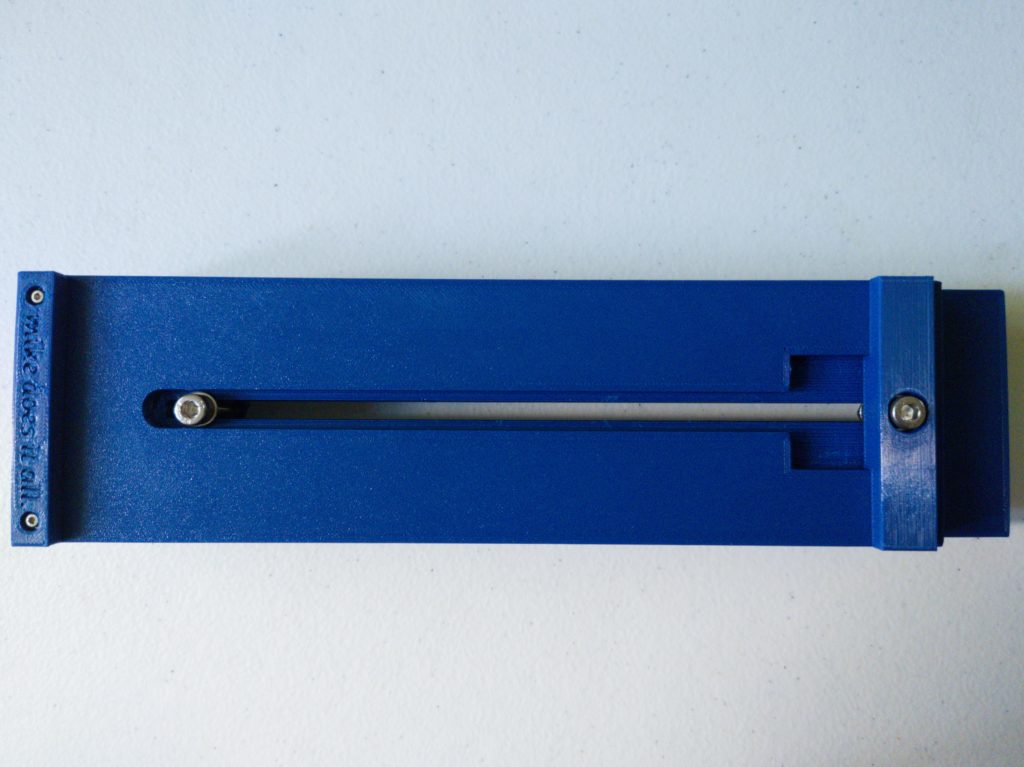

mini-makes: 3D printed whetstone sink bridge

Whether you’re a home cook, amateur chef, or professional, a sharp and well maintained knife is a kitchen essential. Not only is a sharp knife a safer knife, but it will make all the tasks required of it a lot easier and more efficient. Once you’ve used a razor sharp knife, it’s difficult to go back to anything else. Keeping your knives razor sharp is a lot easier than most people would think. Although not an essential tool for sharpening your knives, a sink bridge is helpful to keep your stone wet (if it’s a water stone) and keep the wet mess in the sink.

Initially, I looked to see what was offered and found several different ones ranging in price from $30 to as much as $60+. I figured I could print my own for a fraction of the cost, so that’s what I did. I modeled my sink bridge off one I saw being sold for $60. I quickly drew it up in Fusion 360 and designed all the dimensions for my specific stone, sink, and the hardware I had on hand.

The result is a whetstone sink bridge made of PETG (for water resistance and strength). It fits my whetstone and sink perfectly and I can’t wait to put it to use giving my knives a good sharpening. To be honest, I would have liked to design things a little differently, but I didn’t want to have to go out and spend money on hardware just for this. As designed, it is definitely rigid enough to withstand the downward pressure required to sharpen knives, which is all that is required. I’m curious how long it will last, but considering it cost less than $10 worth of materials, I’m not too concerned.

Either end includes a lip to sit upon the sink edge while the channel allows the bridge to be extended for use and collapsed for storage. The screws are secured with washers and nuts to keep the bridge sturdy when extended. The top bracket is also adjustable to accommodate shorter stones. I also designed the bottom holder to be screwed on instead of printed as one piece. This allowed me to print the top piece without using a lot of support structure and as a result, only the channel required support structure.

Comments welcome!